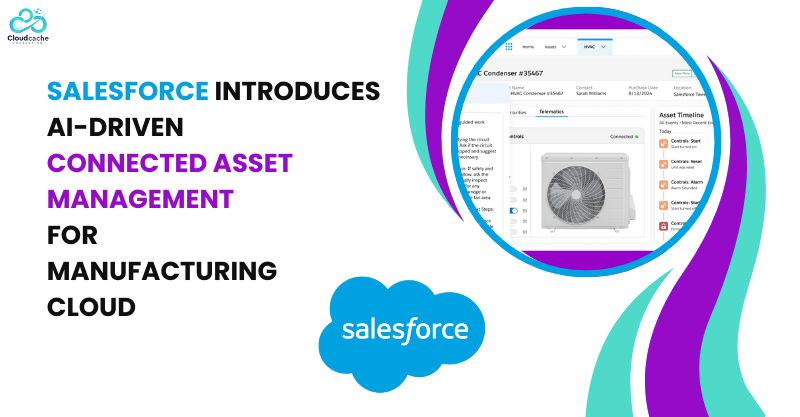

Salesforce Introduces AI-Driven Connected Asset Management for Manufacturing Cloud

Salesforce recently introduced its new product ‘Connected Assets’, an additional suite of capabilities for its Manufacturing Cloud. This innovation gives manufacturers a comprehensive, real-time view of their connected asset data—including service history, status, telematics, and customer information.

Need?

Empower manufacturers to manage assets effectively, predict performance issues, and act proactively using real-time insights.

With Connected Assets, teams across field operations, customer service, and sales can deliver:

- Real-time alerts for enhanced customer engagement.

- Personalized offers and faster support.

- Accelerated repairs for reduced downtime and heightened customer satisfaction

AI: The Heart of Connected Asset Management

The introduction of AI-powered capabilities enhances the suite by offering:

- Actionable Insights: AI analyzes asset performance, service history, and real-time data to recommend proactive maintenance measures.

- On-Site Assistance: For instance, AI can guide technicians to address a failing tractor engine and related components, avoiding future disruptions.

- Generative AI Integration: Powered by Salesforce Industries AI, manufacturers can leverage tailored prompts and industry-specific data models to summarize asset alerts, cases, work orders, and warranty statuses. This streamlines customer support and uncovers new revenue opportunities.

Key Benefits of Connected Assets

- Unified Asset View: Gain a consolidated perspective on telematics, IoT data, and customer service history.

- Proactive Maintenance: Predict and address issues before they escalate, reducing costly downtime.

- Enhanced Decision-Making: Equip teams with real-time data for informed, timely responses.

- Optimized Performance: Monitor health and performance metrics to maximize operational efficiency.

Why It Matters: Tackling Downtime Losses

Only 42% of manufacturers have the integrated data to monitor their assets effectively globally. By consolidating asset data, Connected Assets helps minimize downtime, reduce costs, and unlock new revenue streams.

How Connected Assets Works

Connected Assets utilizes over-the-air (OTA) technology to facilitate data sharing between the cloud and physical assets. This seamless integration offers manufacturers a contextualized view of their equipment’s status, usage patterns, and maintenance history.

Features of Connected Assets

- Unified Data Integration:

The Data Cloud for Manufacturing consolidates structured and unstructured data from telematics and ERP systems. This unified model simplifies monitoring, analysis, and proactive customer engagement.

- Comprehensive Asset Insights:

The Connected Digital Asset tool provides sales and service teams with a holistic view of an asset’s history, condition, and real-time performance. For example, a sales representative can identify an aging machine and offer a discounted upgrade.

- Performance Monitoring

With Asset Performance Monitoring, teams can track key metrics to identify potential issues and alert customers, avoiding production disruptions.

- Real-Time Telematics

The predictable Telematics Framework allows teams to take action with real-time data. For instance, if a tractor shows excessive fuel usage, an alert can automatically prompt the customer to schedule a service appointment.

- Predictive Maintenance

Asset Service Prediction, part of Salesforce Field Service, leverages AI to anticipate maintenance needs and provide real-time repair recommendations, reducing service visits and ensuring faster resolutions.

- Generative AI Summaries

Asset Service Summary, powered by Einstein AI, auto-generates comprehensive overviews of alerts, work orders, and warranty statuses, enabling faster customer support and new revenue opportunities.

- AI-Powered Telemetry

It mines sensor and IoT data to deliver asset health’s actionable snapshots. For instance, it can detect an engine’s declining performance and automatically initiate a work order.

Expanding Asset Management Beyond Manufacturing

Salesforce’s Connected Assets is not limited to Manufacturing Cloud. It is now available for:

- Energy & Utilities Cloud

- Communications Cloud

- Media Cloud

This cross-industry availability enables diverse sectors to extract value and drive efficiency from their connected assets.

Pricing

- Connected Assets features, including Asset Performance Monitoring and Actionable Telematics Framework, are available with Manufacturing Cloud Enterprise or Unlimited Editions.

- Access to Field Service and its predictive insights can be purchased separately.

- Data Cloud and Einstein AI features, such as Asset Warranty Summary, are also available as separate add-ons.

The Future of Manufacturing with Salesforce

By combining real-time connected asset data with cutting-edge AI capabilities, Salesforce’s Connected Assets empowers manufacturers to reduce downtime, optimize performance, and enhance customer satisfaction. With this suite, industries can mitigate losses and uncover new opportunities for growth and innovation.

Discover how CloudCache Consulting can help you redefine your approach to asset management today.